Wheel Building

DISCLAIMER |

The information in this document is information is presented "as is", without warranty of any kind, either expressed or implied, including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose. The entire risk as to the quality and performance of the information is with you. Should this information prove defective, you assume the cost of all necessary servicing, repair, correction, medical care or any other remediation.

If this is not acceptable to you, you may not read this material.

|

A Few Core Principles of Wheel Building

Inbound and Outbound Spokes

A hub has two flanges. Any spoke pushed through the outside of a flange to the inside is called an inbound spoke. Any spoke pushed from the inside to the outside of a flange is called an outbound spoke. See the following graphic:

The concept of inbound and outbound spokes will be vital for many reasons. The most obvious is that if you insert all inbound spokes first, you'll have a

much easier time lacing the wheel.

Also, many people believe that on a rear wheel, the inbound spokes should be the pulling spokes. However, if you have a hub brake in back, there's some justification for having the outbound spokes do the pulling, so that when you hit the brakes and pulling reverses, the huge tension is on the inside spokes. When you prioritize factors in lacing a wheel, I'd say that whether pulling comes from the inbound or outbound spokes is a low priority.

Sometimes in this document I call inbound spokes "inner" or "inside", and outbound spokes "outer" or "outside". You know what I mean.

However , some websites refer to inbound spokes as "trailing" or "pulling" spokes, or even "leading" or "pushing". As a concept that's just plain wrong, although perhaps on those websites the inbound spokes either always pull or always push, so in the special case of the those websites it's OK. But as a concept it's wrong, because as you'll see later, you can lace a wheel so that the inbound spokes pull

or push.

Symmetric and Asymmetric Wheels

A symmetric wheel is one where the inbound spokes all go the same direction, and the outbound spokes all go the opposite direction from the inbound spokes. For instance, an inbound-pull wheel viewed from the drive (cog) side has all inbound spokes, on both flanges, going counterclockwise from hub to rim, while the outbound spokes all go clockwise to reach the rim.

An asymmetric wheel is one where the inbound spokes on one flange pull while on the other flange they push. When viewed from the drive side, the closer flange's inbound spokes go counterclockwise to the rim while the farther flange's inbound spokes go clockwise to the rim. Or vice versa. On an asymmetric wheel, the inbound spokes of one flange go the same direction as the outbound spokes of the other flange.

All other things being equal, most folks prefer symmetric wheels. They're conceptually simpler, and therefore easier to build. However, with some combinations of rim polarity (discussed later) and hub spoke hole bevel polarity (discussed later), the only way to box the wheel (discussed later)

and conform to the rim polarity

and conform to the hub spoke hole bevel polarity is to create an asymmetric wheel. That's a small price to pay, because violating rim polarity orhub spoke hole bevel polarity causes broken spokes and maybe wheel instability. Creating an asymmetric wheel is discussed later.

Boxing the Valve

To facilitate easy filling with air, the bike's valve must be boxed, meaning it doesn't conflict with a spoke on either side of it.

| CORRECT |

WRONG |

WRONG |

REALLY WRONG |

|

|

|

|

| Valve is clear of spokes on either side. |

Valve conflicts with spoke on its right. |

Valve conflicts with spoke on its left. |

Valve conflicts with spokes on both sides. |

When you build a wheel, you must box the valve. That means planning ahead, which will be explained later.

Rim Polarity

Most rims stagger the spoke holes to alternate sides of the rim's center circumference.

|

|

Most rims stagger the spoke holes to alternate sides of the rim's center circumference, as shown in the graphic to the left. The valve hole is not visible in the graphic, but instead is on the bottom side where it can't be seen.

Notice that every other hole is offset to the left of the center circumference, with alternating holes offset to the right. It's ABSOLUTELY essential that spokes from the left hand hub flange go to left-offset rim holes, and spokes from the right hub flange go to the right-offset rim holes.

If you were to do it the other way, spokes would cross the center circumference, with each spoke entering the rim at an unacceptably shallow angle rather than the preferable 90 degrees (perpendicular).

The necessity of not crossing the center circumference constrains your wheel building possibilities. |

When the valve hole is placed, there are two possibilities:

|

Left on top |

Right on top |

| Viewed top outside of rim: |

|

|

| Viewed inside of the rim with the valve hole far away from you |

|

|

|

|

|

|

Viewing the , the spoke hole on the valve hole's left is higher than the one on the right. |

Viewing the inside of the hub with the valve hole far away from you, the spoke hole on the valve hole's right is higher than the one on the left. |

Hub Spoke Hole Bevelling

|

|

Some hubs have bevelling (I'd call it countersinking, but as you'll see later the spoke heads do NOT go on the bevelled side) if you look at any side of any flange on the hub. The diagram at the left is an example.

Some hubs have holes bevelled on both sides, so that it makes no difference which side you stick the spoke in. But others have holes bevelled on one side only, with bevelling direction alternating on the flange. On the diagram to the left, the holes that don't appear bevelled are bevelled on the other side of the flange.

The purpose of the bevel is NOT to house the spoke head. Instead, the purpose is to match the curve of the spoke coming out of its head, so that the spoke is not continuously cut by a sharp right angle. When holes have bevels only one one side, ALWAYS stick spokes into the non-bevelled side. |

Once again, the purpose of the bevel is NOT to house the spoke head. Instead, the purpose is to match the curve of the spoke coming out of its head, as shown in the following cutaway diagrams of spokes fitting in bevelled spoke holes:

| Right Way |

|

Wrong Way |

|

|

|

| This is the right way. The bevel supports and caresses the curve of the spoke, while the hard edge stops the spoke head from slipping through |

|

This is the wrong way. The curve of the spoke is left to bend around the right angle and then be cut by that right angle. |

|

NOTE

Most modern hubs are either unbevelled or bevelled the same on both sides of each hole. Such symmetrical bevelling or lack of bevelling eliminate situations where you have to choose between a boxed wheel, a symmetric wheel, or a strong and stable wheel.

Nevertheless, ALWAYS check the hub to find out about the bevelling. If bevelling is asymmetric and you lace the hub with spoke heads going into the bevel, you're going to be breaking a lot of spokes. |

So to summarize, on hubs where half the holes are bevelled on one side and half on the other, always insert spokes in the non-bevelled side. Otherwise your spokes will fail early, shearing off near the head. This requirement puts yet another constraint on your lacing, requiring intricate planning.

If your hub's holes are bevelled on both sides or neither side, you have more choices, which effectively translates into the ability to build a symmetric wheel no matter what.

Hub Polarity

On a 36 spoke hub there are 18 holes on each flange. These holes DO NOT line up, but instead are staggered. the following drawing shows two hubs with bevelled holes represented by circles and non-bevelled holes represented by stars. Notice that the holes on the two flanges don't line up, but instead alternate:

Notice that in the left drawing, front flange (red) bevels are a little clockwise of their back flange (yellow) counterparts. On the right drawing, the front are a little counterclockwise of the back. These are the two possible polarities of a hub with bevels, and you must account for this variable so that all your spokes are inserted from the non-bevelled to the bevelled side, rather than the other way around.

Later in this document we'll refer to front leads clockwise as "right beveled", and we'll refer to "front trails clockwise" as "right non-bevelled", and we'll make the point that right bevelled hubs are compatible with rims with the hole just right of the valve on top, while right non-bevelled hubs are compatible with rims with the hole just right of the valve on the bottom. When there's an incompatibility, either boxing, symmetry or wheel strength, durability and stability must be sacrificed. The obviousl thing to sacrifice in such cases is symmetry, and we'll show you how to do that.

Cross Number

Wheels can be built radial (zero cross), 1 cross, 2 cross, 3 cross, 4 cross, or on 48 spoke wheels even 5 cross. As far as I'm concerned, radial spoking is a race inspired fad that saves a few grams and, makes the wheel much less robust for cornering and on the back wheel makes accelleration squishy, like an old distorted chain would do. Don't even get me started on 18 spoke wheels. When I want a good, solid wheel for transportational use, I go 3 or 4 cross. I've drawn 1, 2 and 3 cross wheels because lower cross wheels are easier to draw. For simplicity, only the spokes from the front flange are drawn, because the cross number refers to how many spokes

from the same flange are crossed.

|

|

1 cross wheel. Each spoke crosses one other spoke from the same flange. |

|

|

2 cross wheel. Each spoke crosses 2 spokes from the same flange. In this case, starting from the hub, one spoke is crossed almost immediately after leaving the hub, and the other is crossed about half way to the rim. |

|

|

3 cross wheel. Note that the only way it could be drawn is by shrinking the hub flange and making the spokes look thinner.

Each spoke crosses three others from its flange. Starting from the hub, the first cross is right at the flange, the second is an inch or two out from the flange, and the third is about half way to the rim.

Notice that in this three cross wheel, the spokes come off the flange almost tangentially. All other things being equal, tangential flange departure is the best for transmitting power or braking with a hub brake. However, tangential departure isn't too good for supporting weight or taking bumps. It's usually best not to go completely tangential, especially given that exact tangential departure will bring a spoke very close to the head of the first spoke it crosses, creating problems.

For this reason, 3 cross is better than 4 cross for large flange hubs with 36 spokes. |

|

|

This is a 4 cross wheel. I halfed the size of the hub and it still wasn't enough to keep each spoke from running closer to the center than the heads of the first spoke it crosses. In other words, it's beyond tangential, which is disfunctional. For functionality, the hub would have had to have been even smaller.

To understand the intracicies of this wheel, click it and you'll be served up a triple-sized image. |

Interlacing

We'll define interlacing shortly, but first a little review.

Spokes on non-radial wheels cross each other. On a 3 cross wheel, every inbound spoke crosses 3 outbound spokes from the same flange, and every outbound spoke crosses 3 inbound spokes from the same flange. Since all of an inbound spoke is on the inside of the hub, and all but the head of an outbound spoke is on the outside of the hub, the simplest way for spokes to cross is for the outbound spokes to cross on the outside, and inbound spokes to cross on the inside. In other words, for a given hub, when you're looking at the wheel from the outside, on the flange closest to you, the outbound spokes cross

over the inbound spokes, and the inbound spokes cross

under the outbound spokes.

The preceding paragraph describes a

non-interlaced wheel. On an

interlaced wheel, the outermost cross is in the opposite direction. In other words, on a 3 cross wheel, starting from the hub, outbound spokes cross over over under, while inbound spokes cross under under over. On a 4 cross wheel, starting from the hub, outbound spokes go over over over under, while inbound spokes go under under under over.

In summary, an interlaced wheel is a wheel where the crosses closest to the rim are the opposite polarity of the other crosses, and the opposite polarity of how the spokes come out of the flange.

In the old days, some people called interlacing "cross spoking."

Why Interlace?

Interlacing makes the wheel stiffer because that last cross forces the inbound and outbound spoke against each other. Hard. Friction between those spokes makes for less movement than there would be otherwise. To the extent that the spokes do not move against each other, the wheel becomes less like a spoked wheel and more like a solid one.

One could argue that the spoke to spoke friction consumes energy, thus making your wheels and therefore your wheel slower. Nominally, the physics is sound, but I doubt the frictional effect would be significant compared to tire friction, chain friction, and of course the big kahuna, wind resistance. I've heard that the 1970's bicycle guru Eugene Sloan recommended soldering a thin wire around each outer cross to eliminate all slippage. That would certainly eliminate the spoke friction energy loss, but I highly discourage it.

The bottom line is this: Interlacing is "settled law." It's been done at least since the late 1960's, and probably a lot longer. Every professionally laced 3 or 4 cross wheel I've ever seen is interlaced. Factory made wheels are interlaced. I argue with much "established wisdom" in the bicycle world, but even I would not build a wheel without interlacing it.

Interlace your wheels. It's easy and makes them stiffer and more stable.

Interlacing and this Document

The spoke lacing instructions in this document automatically produce interlaced wheels because they instruct you to put your outbound spokes over the first two crossed spokes and under the last one (for three cross). This interlacing discussion is included so you understand why you do this, and the importance of doing it.

Dishing

The rim should be midway between the fork ends, which is not necessarily midway between the hub flanges. When the nuts butting up against the insides of the forks are at different distances from their respective hub flanges, then to the degree possible you must offset the hub 1/2 the difference between the fork to flange distances, toward the fork that's farther from the flange. See the following out of proportion diagrams.

|

|

|

| Dished Wheel |

|

Undished Wheel |

What's not shown in the preceding diagrams is that the right side of the dished hub has a gear cluster requiring the right fork end to be much farther from the right flange than the left fork end is to the left flange.

WARNING: In no situation should the rim sit directly over the flange on the dished side. That would make a weak wheel that could collapse unexpectedly, especially if making a sharp turn away from the dished side. If, looking down, you line up the top and bottom of the rim on the dished side, the flange and at least a little of the spokes should be visible. It's better to have the wheel off center in the forks than have the rim and flange form a plane. I've read elsewhere that the angle off the hub should be at least 10 degrees, but I don't personally know how good that number is.

Click here to see the math behind wheel dishing with a complete diagram.

Grease the Threads and Nipple Seat

Greasing the spoke threads, the nipple's threads inside the nipple, and the area where the nipple sits on the rim, makes it easier to turn the spoke nipples and minimizes thread friction twisting the spokes. Grease makes it a little harder to work with your hands, but over the years when you need to true your wheels, you'll thank yourself for the extra effort on building. On completion and truing of the wheel, and before installing the rimstrip, tube or tire, you should wipe off excess grease with a rag.

Assumptions Made in this Document

This document assumes you're fairly handy with bicycles and bicycle tools. Wheel building

should not be your first attempt at bicycle repair. Even most experienced bicycle mechanics aren't particularly fast or good at it. Economics dictate that most of the time, the bike shop solution to a broken rim is a brand new factory assembled wheel. Even for an experienced mechanic, building a wheel takes between 3 and 20 times longer than changing a flat tire.

This document assumes you have the necessary tools -- a flathead screwdriver for quick initial spoke nipple adjustment, a decent spoke wrench of the right size, and whatever tools you need to remove a freewheel (remove it before taking the old wheel apart!). If vision is an issue, have excellent lighting and good glasses. Make yourself a good workspace consisting of at least a chair and a small table to keep tools on, unless you're using a truing stand.

Speaking of truing stands, this document assumes you're not a racer or a guy with five hundred dollar wheels. If you want the best of the best wheels,

do not use the techniques in this document. As a matter of fact, for the ultimate results you'll want to have your wheels custom built by a professional wheelbuilder (which I'm most certainly not).

This document assumes you're a transportational cyclist who busts up your spokes and rims a lot, and wants to build new wheels cheaply -- possibly with rims or spokes from a garage sale wheel or even a dumpster wheel. This document assumes you don't have specialized wheel building tools like a truing stand or a dishing measurement tool -- you'll use your rear forks as a truing stand, and you'll use your eyeballs to dish your wheel.

Last, but

certainly not least, this document assumes you have spokes of the proper length for your hub, rim and desired cross pattern. Perhaps you're just replacing a rim with a rim of the same diameter.

If you don't have proper length spokes, bring your hub and rim to a reliable and knowledgeable bike shop, tell them your desired cross pattern, have them sell you spokes, and have them guarantee those spokes are the right length for your hub, rim and desired cross pattern. Expect to pay at least a buck apiece for the spokes -- it's worth it if they're good, strong stainless steel spokes of the right length. The bike shop might give you two different lengths -- slightly shorter spokes for the drive side and slightly longer spokes for the non-drive side. Don't mix them up.

This document assumes you don't care about oh-so-hip or exotic spoking patterns. Not discussed here are radial spoking (bad idea, especially on rear wheels), crowsfeet spoking, leaving out half the spokes, different cross numbers for each flange, and the like.

This document assumes you're not one of those people who believe that once a wheel has been laced a little wrong or stressed in any way, the rim and spokes are damaged and must be thrown out. This document does not assume that you have a spoke tension guage, and everyone who really does regular 50 mile weeks over potholes, railroad tracks and curbs knows there's nothing wrong with a wheel that's round and straight but must have spokes at different tensions to achieve that. This document takes the position that rims and spokes are not disposable items to be thrown away the first time a wheel is bent slightly.

There are many people who would argue with the preceding paragraph. They might claim that if you have eight hundred dollar wheels built

just so by a professional wheelbuilder, they'll never bend. Yeah, whatever, try that when you weigh over 200 pounds and often carry over 50 pounds of stuff in your rear baskets, jump curbs and railroad tracks, and ride on streets with cars and potholes. But anyway, if you really believe in the everlasting expensive wheel whose truing never involves making spoke tension uneven, then this is by far the wrong document for you.

If you care how many grams you save by changing your spoking pattern, this document is not for you. If you put a lot of priority on aesthetics, you might not like this document. If you're a bicycle snob espousing theories that come directly or indirectly from the racing or bike shop world, this is very much the wrong document, as all it does is tell you how to build 3 or 4 cross wheels suitable for transportational biking.

Lastly, if you're a transportational cyclist who wants to build his own wheels, either with purchased parts or scavenged parts,

I wrote this document just for you!

Theory: The First Two or Three Spokes

The entire intelligence of your lacing pattern is set by the first two, or once in a while three spokes you insert. After those two or three are installed, the rest is just following patterns and goes very quickly if you have nimble hands, good eyes and a decent attention span (I have none of those three attributes and I still do fairly well). So spend extra time on the first two or three spokes. That way you won't get to the end of the wheel and have to take it apart and do it over again.

To repeat: The first two or three spokes define the entire lacing pattern of your wheel!

Be Safe, Label Your Rim

With only two spokes in your rim, it's easy to accidentally twist the hub so that things are not how you think they are. This can lead to time consuming problems. Before installing any spokes, lay your rim down flat on a table or the ground and label the top side "drive". Depending on the kind and cost of the rim, you can use marker pen, nail polish, tape or whatever. Just make sure there's an easily recognizeable mark indicating on side is the drive side.

Start by Testing for Rim Polarity/Hub Bevel Sequence Conflict

A certain combination of rim polarity and hub bevel sequencing makes it impossible to build a symmetrical wheel that is strong, boxed and symmetric. You certainly don't want to sacrifice strength, filling an unboxed wheel with air is a hassle, so you'll want to build an asymmetric wheel if you have this conbination, which I phrase as a conflict. This section tests for that combination. Let's get started:

- Are the rim's spoke holes all in a single line, or do they alternate left and right as you go around the rim? If they are all in a single line, there's no possible conflict, so proceed to the Install the First Two or Three Spokes article and choose one of the symmetrical options.

- Looking at the outside of each flange on the hub, do the holes appear to alternate between bevelled and non-bevelled holes? If not,there's no possible conflict, so proceed to the Install the First Two or Three Spokes article and choose one of the symmetrical options.

- Viewing the rim horizontally from the inside as shown below, is the spoke hole just right of the valve hole on the top half or the bottom half? Write it down, right hole on bottom or right hole on top.

Right hole on top |

|

Right hole on bottom |

- Viewing the hub on the drive side, with a non-bevelled hole visible on the drive flange at the 12 o'clock position, look at the non-drive flange hole visible just barely to the right (clockwise) of the non-bevelled drive flange hole. Is that non-drive flange hole to the right bevelled or not bevelled. Write it down -- right bevelled or right non-bevelled. See the following illustration to clarify this instruction:

Right bevelled |

|

Right non-bevelled |

Compatible with right

hole on top rim. |

|

Compatible with right

hole on bottom rim. |

- Now use the following matrix to find out what kind of wheel to build:

|

Hub right bevelled |

Hub right non-bevelled |

| Rim right hole on top |

Compatible. Build a symmetric wheel. |

Incompatible. Build an asymmetric wheel. |

| Rim right hole on bottom |

Incompatible. Build an asymmetric wheel. |

Compatible. Build a symmetric wheel. |

- Armed with the preceding information, proceed to the Install the First Two or Three Spokes article and choose the proper option.

Install the First Two or Three Spokes

This section contains instructions to install first spokes for these three kinds of wheels:

If you haven't done it yet, take the test in the section titled

Start by Testing for Rim Polarity/Hub Sequence Conflict . If that test revealed a conflict between rim polarity and hub sequence then your

only choice is

Asymmetric: First Three Spokes . Otherwise, you can choose between and , depending on whether you want your inside spokes or your outside spokes to pull. Inside-pull is preferred by most, although if the wheel has coaster brakes, disc brakes or another type of brakes attached to the hub, outside-pull offers the advantage of letting the inside spokes take the tension during braking. Bottom line, inside-pull is a good default choice, but choosing inside-pull or outside-pull is not an earth shaking decision -- an excellent wheel can be built with either. However, if you have a conflict between rim polarity and hub bevel sequencing,

Asymmetric: First Three Spokes is your only choice.

Ok, let's get started. Please pick the appropriate wheel:

Symmetric Inside Pull: First Two Spokes

Your two finished spokes for an inside pull wheel will look like one of the following two illustrations, depending on whether you have a right on top or right on bottom rim:

|

|

|

| If rim is right hole on top. |

|

If rim is right hole on bottom. |

In the preceding illustrations, the red flange is the drive flange. Note that both spokes are inbound -- one from the drive flange and one from the non-drive flange.

In the following instructions, if the rim has all holes lined up in the center, use the right hole on top build.

- Hold the hub drive side up.

- Drop an inbound spoke through a non-bevelled hole in the drive side flange.

- Holding the hub drive side up and with the rim's drive side marking up, if the hole just right of the valve (viewed from the inside of the rim) is on top, screw the spoke into that hole. Otherwise screw it into the second hole right of the valve.

- If the spoke is screwed into the hole just to the right of the valve hole, push an inbound spoke up through the non-drive flange hole just barely to the right (clockwise) of the drive side flange hole containing a spoke. If the spoke is screwed into the second hole right of the valve hole, push a spoke up through the non-drive flange hole just barely to the left (counterclockwise) of the drive side flange hole containing a spoke. Note that in this instruction, all directions such as "right", "left", "clockwise" and "counterclockwise" are as viewed by you from above the drive flange.

- Screw the spoke from the non-drive flange into one of the first two rim holes right of the valve hole, depending on which is vacant.

- Compare your wheel to the illustrations preceding these directions. If your wheel matches the illustration for the proper rim polarity, and if both spokes enter through non-bevelled holes (or if both sides of all holes are bevelled), you're done.

- Once you're done, go on to the Lace the Rest of the Spokes section.

Symmetric Outside Pull: First Two Spokes

Your two finished spokes for an outside pull wheel will look like one of the following two illustrations, depending on whether you have a right on top or right on bottom rim:

|

|

|

| If rim is left hole on top. |

|

If rim is left hole on bottom. |

In the preceding illustrations, the red flange is the drive flange. Note that both spokes are inbound -- one from the drive flange and one from the non-drive flange.

In the following instructions, if the rim has all holes lined up in the center, use the right hole on top build.

- Hold the hub drive side up.

- Drop an inbound spoke through a non-bevelled hole in the drive side flange.

- Holding the hub drive side up and with the rim's drive side marking up, if the hole just left of the valve (viewed from the inside of the rim) is on top, screw the spoke into that hole. Otherwise screw it into the second hole left of the valve.

- If the spoke is screwed into the hole just to the left of the valve hole, push an inbound spoke up through the non-drive flange hole just barely to the left (counterclockwise) of the drive side flange hole containing a spoke. If the spoke is screwed into the second hole left of the valve hole, push a spoke up through the non-drive flange hole just barely to the right (clockwise) of the drive side flange hole containing a spoke. Note that in this instruction, all directions such as "right", "left", "clockwise" and "counterclockwise" are as viewed by you from above the drive flange.

- Screw the spoke from the non-drive flange into one of the first two rim holes left of the valve hole, depending on which is vacant.

- Compare your wheel to the illustrations preceding these directions. If your wheel matches the illustration for the proper rim polarity, and if both spokes enter through non-bevelled holes (or if both sides of all holes are bevelled), you're done.

- Once you're done, go on to the Lace the Rest of the Spokes section.

Asymmetric: First Three Spokes

Your three finished spokes for an asymmetric wheel will look like one of the following two

very out of proportion illustrations, depending on whether you have a right on top or right on bottom rim:

|

|

|

| If rim is right hole on top. |

|

If rim is right hole on bottom. |

In the preceding illustrations, the red flange is the drive flange. Note that the red spoke and the blue spoke are inbound, but the blue and green spoke is outbound.

In the following instructions, if the rim has all holes lined up in the center, use the right hole on top build.

- Hold the hub drive side up.

- Drop an inbound spoke through a non-bevelled hole in the drive side flange.

- Holding the hub drive side up and with the rim's drive side marking up, if the hole just right of the valve (viewed from the inside of the rim) is on top, screw the spoke into that hole. Otherwise screw it into the second hole right of the valve.

- If the spoke is screwed into the hole just to the right of the valve hole, drop an out bound spoke through the non-drive flange hole just barely to the right (clockwise) of the drive side flange hole containing a spoke. If the drive side spoke is screwed into the second hole right of the valve hole, drop an out bound spoke through the non-drive flange hole just barely to the left (counterclockwise) of the drive side flange hole containing a spoke. Note that in this instruction, all directions such as "right", "left", "clockwise" and "counterclockwise" are as viewed by you from above the drive flange.

- Screw the spoke from the non-drive flange into one of the first two rim holes right of the valve hole, depending on which is vacant.

- Push an inbound spoke up through the nondrive flange hole immediately counterclockwise to the nondrive flange hole already containing a spoke.

- Prepare yourself for quite a bit of counting. I'll make it as painless as I can, but it will still be difficult. On the rim, starting from the rim hole containing the spoke outbound from the nondrive flange, count this many holes clockwise:

| Wheel Geometry |

|

Rim holes to go counterclockwise |

| 1 cross |

|

2 |

| 2 cross |

|

6 |

| 3 cross |

|

10 |

| 4 cross |

|

14 |

- After counting, fasten the inbound nondrive flange spoke to that hole. Check that there are that number minus one rim holes between the two spokes from the nondrive flange. Be very careful to count between nondrive spokes, rather than accidentally counting between the drive side spoke and the far nondrive spoke.

- Understanding that a mistake on this spoke will not be detected until the wheel is almost built, resulting in lots of frustration and wasted time.

- You're done. Go on to the Lace the Rest of the Spokes section, remembering you're building an asymmetrical wheel.

Lace the Rest of the Spokes

Congratulations! All lacing tasks requiring thought have been completed. The rest is simply following trivial patterns. Oh don't get me wrong, you still have to be careful or a careless mistake will result in an egg you must take apart and redo, but if you're careful the rest of lacing is easy. If you have good eyes and good hands, it's also going to be fast.

Also, with one small exception, the instructions in this section are one size fits all, whether you're going inside pull, outside pull, or asymmetrical. Whether your rim is right top or right bottom. Regardless of your hub's bevelling or lack thereof. When you installed the first two or three spokes, that was the majority of the thinking, and it defined the wheel's contruction.

Install Inbound from the Drive Flange

- Holding the hub drive side up, drop the other 8 inbound spokes through the drive flange. Remember if you're using two different spoke lengths, they should be drive side spokes. They should be dropped at every second holes in the drive flange, starting with the one two holes counterclockwise of the mounted drive side spoke.

- Be very careful that your hub hasn't twisted. Make sure the drive side of the hub is facing the same direction as the side of the rim you marked as the drive side.

- On the hub, grab the next spoke clockwise from the mounted one, and loosely screw it in four rim holes clockwise from the mounted drive side spoke. Note there should be three holes separating the newly mounted spoke from the one mounted before.

- Continue clockwise around the wheel, taking the spoke 2 holes clockwise on the hub from the last, and screwing it into the rim 4 holes clockwise from the last one from this side. On the rim, there should be three spoke holes separating this one from the last.

- When all drive side inbound spokes have been installed, look over the wheel to detect any glaring errors. Everything on the drive side should look sort of even.

This Instruction is for Asymmetric Wheels ONLY.

- Skip this unless you're building an asymmetric wheel.

- On the non-drive side you previously installed one inbound and one outbound spoke. At this point the outbound spoke does more harm than good.

- Carefully find the outbound spoke from the nondrive side, unscrew it and remove it. Be very careful, because if you remove the inbound spoke you'll have quite a bit of remedial work to do, or possibly you'll have to start over.

- Put the removed spoke and spoke nipple with your other nondrive side spokes and nipples.

Install Inbound from the Non-Drive Flange

- Holding the wheel non-drive side up, drop the other 8 inbound spokes through the drive flange. Remember if you're using two different spoke lengths, they should be non-drive side spokes. They should be dropped at every second holes in the drive flange, starting with the one two holes counterclockwise of the mounted drive side spoke.

- On the hub, grab the next spoke clockwise from the mounted one, and loosely screw it in four rim holes clockwise from the mounted non-drive side spoke. Note there should be three holes separating the newly mounted spoke from the one mounted before.

- Continue clockwise around the wheel, taking the spoke 2 holes clockwise on the hub from the last, and screwing it into the rim 4 holes clockwise from the last one from this side. On the rim, there should be three spoke holes separating this one from the last.

- When all drive side inbound spokes have been installed, look over the wheel to detect any glaring errors. Everything should seem reasonably even, unless the hub is twisted to alter the appearance.

Install Outbound from the Drive Flange

- Keep the wheel non-drive side up.

- Drop all 9 outbound spokes through the drive flange, which because you're non-drive up, is the lower of the two flanges. Remember if you're using two different spoke lengths, they should be drive side spokes. If you've done everything right so far, they should consume every empty spoke hole on the drive flange, and they should alternate holes.Lightly twist the hub counterclockwise for outside-pull wheels, or clockwise for inside-pull and asymmetrical wheels.

- Grab any of the outbound spokes. Angle it the same direction you just twisted the hub.

- On 3 cross wheels, pass the outbound spoke over 2 inbound spokes from the same flange, and then under the third inbound spoke from the same flange. Loosely screw it in the rim 2 rim holes after the spoke you passed under. On 4 cross wheels, pass over 3, under 1, and still loosely screw it in 2 past the one you went under.

- Grab the next outbound spoke clockwise on the hub, go over-over-under for 3 cross, or over-over-over-under for 4 cross, and loosely screw it in 2 rim holes past the spoke you went under.

- Continue until all outbound spokes on this side are loosely screwed in.

- When all outbound spokes on this side have been installed, look over the wheel to detect any glaring errors. Everything should seem reasonably even and it should begin to have been formed like a real bicycle wheel.

Install Outbound from the Non-Drive Flange

- With drive side up, drop all 9 outbound spokes through the drive flange, which because you're non-drive up, is the lower of the two flanges. Remember if you're using two different spoke lengths, they should be drive side spokes. If you've done everything right so far, they should consume every empty spoke hole on the non-drive flange, and they should alternate holes.

- Grab any of the outbound spokes. Angle it the against the inbound spokes from the same flange.

- On 3 cross wheels, pass the outbound spoke over 2 inbound spokes from the same flange, and then under the third inbound spoke from the same flange. Loosely screw it in the rim 2 rim holes after the spoke you passed under. On 4 cross wheels, pass over 3, under 1, and still loosely screw it in 2 past the one you went under.

- Grab the next outbound spoke clockwise on the hub, go over-over-under for 3 cross, or over-over-over-under for 4 cross, and loosely screw it in 2 rim holes past the spoke you went under.

- Continue until all outbound spokes on this side are loosely screwed in.

- When all outbound spokes on this side have been installed, look over the wheel to detect any glaring errors. It should look like a real bike wheel, and will even have a tiny bit of rigitity to it, although the hub can be pushed either direction or twisted a little bit.

- Your wheel is now laced. Go on to section "To Dish or Not to Dish".

To Dish or Not to Dish

Something you need to do is consider early in truing is whether the wheel needs

dishing . Dishing is where the spokes on one side (usually the drive side) are pulled tighter and shorter than on the other side. This is done because you want the rim centered between the frame forks, not between the flanges. Measure from each flange to its respective inner fork mount nut. Displace the rim 1/2 the difference between the two measurements. In other words, if the drive side's inner fork nut is 1.75 inches from the drive side flange, but the non-drive side inner fork nut is only 0.75 inches from its respective flange, then the difference is 1 inch so you'd displace the rim toward the drive side by half that 1 inch difference, for a 1/2 inch displacement.

If you're dishing the wheel, you'll tend to first tighten the side toward which you're displacing (usually the drive side) before tightening the other side. But all in all, it's kind of a judgement call.

My advice is the time to begin dishing dish is when only three or less spokes have loose slack in them, and some of the spokes have begun to tighten just a little bit.

When your wheel is finished, on a dished wheel, when you tap a spoke on the dished side it should make a

ping sound, while on the non-dished side it should sound like

pong . In no case should it sound like

clunk . The dished side should be so tight that it's very hard to squeeze adjacent same-side spokes at their center. On the non-dished side, squeezing adjacent same-side spokes should make them move toward each other by maybe an eighth inch.

On a finished wheel that isn't dished, all spokes should sound somewhere between ping and pong, with no clunks, and all adjacent same-side spokes should move just slightly when squeezed at their centers.

Tightening and gross truing

Initial Tightening

- Make sure you're working in good light and if you need glasses have the right classes cleaned for maximum clarity. You're going to need visual acuity.

- Starting at the valve hole, go around the wheel and tighten every spoke so only a couple threads show on each spoke.

- Starting at the valve hole, go around the wheel and tighten each spoke by exactly one turn. Repeat until most of the spoke nipples are touching the rim.

Initial Dishing

- Starting at the valve hole, go around the wheel and tighten each dish side spoke by one revolution.

- Repeat until the rim begins to approach where it should be on a dished wheel. Stay aware, however, at this stage the wheel has lots of side to side wobble, so when eyeballing the dish, do it at different parts of the wheel.

Intermediate tightening

- Starting at the valve hole, go around the wheel and tighten each spoke by exactly one turn.

- Repeat until a few spokes are downright tight.

- If any spoke nipples are not touching the rim, hand tighten them so they touch the rim (you did remember to grease the threads, didn't you?

Gross Truing

Here are a few tips on wheel truing:

- Never true more than 1/8 of the wheel (45 degrees) at once.

- Keep spinning the wheel, finding the worst part, fixing that, and repeat.

- As a general rule, prefer to true radially before truing side to side.

- Never adjust any spoke more than 1 turn for radial truing, or 1/2 turn for side to side truing.

- When adjusting side to side wobble, the "worst part" is the part farthest from where the rim should be with whatever dishing it should have.

- When gross truing a new wheel, perfer tightening to loosening until the wheel is tight enough to ride.

- When turning a spoke, remember that part of the torque went into twisting, or "winding" the spoke. One reason you used grease on the spoke threads is to minimize spoke winding. After turning a spoke, turn it back a small amount to eliminate the winding. That amount is hardly at all with new, greased spokes, but it can be substatial on old, oxidized wheels. On spokes with a lot of winding, you'll feel how much to unwind it.

- Every few minutes during truing, squeeze together crossing spokes from the same flange. This stresses the wheel and helps get it into a stable configuration, which means you'll have less ugly surprises later in truing or the first few days riding your new wheel.

Spin the wheel. Unless the rim was brand new and very high quality, it will wobble side to side and will be elliptical. In general you true out the elliptical distortion before the wobble. But if gross side to side makes it difficult to measure radial distortion, then get the side to side a little more under control, as explained later.

Spin the wheel and test the radius as it spins. Whereever the rim comes out too far, find the center of the part it comes out too far, making sure that point is between spokes. Tighten either 2 or 3 spokes on each side of that point by a full revolution. Spin again, do the same thing for the part of the rim extending out the most. Continue until the wheel is within 1/16 inch of true, or better. HOWEVER...

It's hard to radially true a wheel when it's swinging wildly side to side, so when the side to side motion makes it difficult to true radially, gross true side to side. Spin the wheel, and at the point where the rim deviates from the desired dish position (or center if there's no dish), tighten the spokes pulling away from the deviation. Typically the center of deviation is at a spoke, so use that as the center and tighten by 1/2 turn 2 or 3 spokes out on each side of that center point, and that spoke itself if it's from the side opposite the deviation. Repeat all this until the side to side is less than a centimeter, and then go back to radial truing.

When things are at least somewhat true both radially and side to side, verify that there's at least some tension on every spoke. If there are just one or two without tension, tighten them slightly. If there are several spokes without tension, start at the valve hole and tighten every spoke on the wheel 1/4 turn. If there are still a lot too lose do another 1/4 turn on every spoke. Be careful -- 1/4 turn on every spoke on an already tensioned wheel will make the wheel extremely tight -- 1/2 turn on every spoke would make it so tight as to be failure prone. When tightening every spoke on an already tightened wheel, never do more than 1/4 turn each without thoroughly retesting the tension.

When the wheel deviates radially less than 1/16 inch and side to side less than 1/4 inch, you're ready for fine truing.

Fine Truing

Tightening and gross truing is a wheel building activity. Fine truing is a maintenance activity. If you're heavy, aggressive or ride on rough roads you'll need to fine true your rear wheel maybe as little as every 20 miles (which would probably indicate you have the wrong wheel for your body weight and riding style). Besides being a maintenance activity, fine truing is also the final step in wheel building.

Here are some principles of fine truing:

- Solve radial problems before addressing side to side problems.

- Side to side is much more sensitive to spoke tensioning than is radial. For instance, if you were to tighten by one turn all spokes within 4 holes of the valve hole, and loosen by one turn the spokes opposite those on the rim, you'd get one or two millimeters of change in radial rim position. But if you tightened by one turn every drive spoke and loosened by one millimeter every non-drive side spoke, you'd move the rim somewhere around a centimeter or more toward the freewheel, depending on how much the wheel was already dished.

- To address radial problems, turn spokes no more than 1 turn before re-checking roundness.

- To address side to side, turn spokes no more than 1/2 turn before re-checking side to side trueness.

- True only the worst place. Once you've addressed the worst place, spin the wheel and address the new worst place. People who try to true the entire wheel at one time end up with eggs or pretzels.

- Your side to side trueness can be no better than your wheel wobble. Tighten your cones before truing your wheel. If you have lousy bearings and cones that must have a little slack to spin freely, loosen them again after the wheel's completely true.

- Blips or swelling on rims make truing very difficult. Either buy new rims or use the locking pliers trick, with a frozen treat stick on the side without the blip if the blip is one-sided. Consult a bike shop to see whether it's safe to use the locking pliers trick on your particular rims.

- Unlike gross truing and tightening, in fine truing you typically loosen some spokes and then tighten others, in order to retain the same overall tension throughout the wheel.

- There's no such thing as perfect. Personally I can get a wheel to 1/16 inch radially, and between 1/4 and 1/16 inch side to side. Professional wheel builders can do much better, but they're still off by a few thousandths. Average people can't do as well as I can, but that's OK. If your wheel is radially true enough that you don't get annoying wheel hop, and side to side true enough that it doesn't drag on your brakes or shimmy your bike, you've done an adequate job.

- Measure roundness on a truing stand, or by placing the wheel in the back wheel forks with the bicycle upside down, and holding a wrench close to the spinning rim.

- Measure side to side using the caliper brakes. For close tolerances, you may need a small flashlight to see clearly.

Radial Fine Truing Procedure

- Hopefully with the tire off, spin the wheel to determine the center and length of the worst run that's too far out or too close in.

- If it's too far out, tighten from the center out to the extent of the eccentricity. Tighten spokes from both sides of the hub. Tighten each spoke no more than 1 turn. Spokes away from the center should be tightened less.

- If it's too close in, loosen from the center out to the extent of the eccentricity. Loosen spokes from both sides of the hub. Loosen each spoke no more than 1 turn. Spokes away from the center should be tightened less.

- Repeat the preceding three steps until the wheel's roundness is acceptable to you.

- If tightening has resulted in an overly tight wheel, or loosening has resulted in an overly loose wheel, you'll need to tighten or loosen every spoke, probably an eighth turn.

Side to Side Fine Truing Procedure

- Spin the wheel to determine the center and length of the worst run that's too far to one side or the other. When choosing "the worst", bear in mind where you want the rim to end up with respect to the flanges and the fork ends to achieve the desired dishing or lack thereof. In other words, consider dishing.

- At the worst place, first loosen the spokes on the side the rim has deviated to, and then tighten the spokes on the other side in order to pull the rim away from the deviation. How many spokes you tighten and loosen depends on the length of the deviant run. How much you tighten and loosen depends on how far to the side the rim deviates, but in no case do you turn a spoke more than 1/2 turn. Try to turn the spokes at the ends of the run less than those toward the center.

- Repeat the preceding two steps until the wheel's side to side trueness is acceptable to you.

- If the fine truing has resulted in some loose spokes, you might have to tighten every spoke on the wheel JUST SLIGHTLY, like maybe 1/8 turn. Having one or two loose spokes often indicates a broken spoke somewhere else, a frozen spoke somewhere else, or a deformed rim, so check for frozen or broken spokes. Personally, I replace broken and frozen spokes, but I just adjust the spokes to strongarm deformed rims into true -- I can't buy a new rim every time I crash or jump off a curb.

A Few Parting Thoughts

Buy or Build?

You can avoid all this. There's a guy on the Internet who will interview you, build you a wheelset of his choosing, and guarantee that wheelset for life. Lose trueness? He'll true it for you. Break a spoke? He'll replace it and true. He doesn't cover rim damage or wear, but if you dent the rim you were doing some pretty agressive riding, and if you wear out the rim, you've gotten many thousands of miles use.

So rather than cobbling together a new wheel every couple thousand miles and regularly truing and replacing spokes, for something between $300 and $900 you can have this guy build your wheels and just enjoy riding. So why am I writing this article?

Well first of all, not everyone has $300 to $900 to spend. Here in Orlando where I live, there are plenty of people using old, beat up bikes for transportation. They don't have $300, but they just might have the time to grab a few dumpster dive wheels, combine the desired hub and rim and a set of spokes that work, and maybe buy a few more spokes to complete the wheel.

Personally, I can afford $900 wheels that will give me 8 years of carefree riding. But I've also had a lot of bicycles stolen, and at least one more run over by a bus. Just because your wheels will last 8 years doesn't mean

you'll be the one riding them all 8.

Then there's the wheelbuilder. After reading this guy's website I really believe he could build me 20,000 mile wheels. But I live hundreds of miles from him, so I can't avail myself of the guarantee. So who do I go to? The true wheelbuilders are hidden amongst the hordes of people basically like me, with a little more practice. I don't want to bet $300 to $900 that a guy really knows what he's doing.

Buy or Build, Part II

It's been years since I was able to buy spokes for less than a buck apiece. That's $36.00 on spokes alone if you build your own wheel. There are many great wheels you can buy prebuilt. Will they last thousands of miles? Probably not, if you're heavy or aggressive. Will they save you a lot of assembly time that you could have spent biking? Probably.

Last time I checked, you could buy a pretty decent coaster brake back wheel for fifty bucks. You couldn't build it for that price if you bought your hub, spokes and rim retail. About 1.5 years ago I bought a wheelset including a 7 speed with coaster brake rear hub for about $250. I had to replace about 20 rear spokes in the last 1.5 years and finally destroyed the rear rim, but geez, I got a great deal, and I just laced a steel rim on the back. I got a year and a half of service over more than 2000 miles.

Unless you can get spokes free or cheap or have the spokes already, or unless you want a very specific rim/hub/spoke combination, it makes more sense to buy the wheel prebuilt. Then later, when it shreds, there will be plenty of time to build it with a different rim and/or spokes.

Truing is Still an Art

If you notice, the lacing part of this document are a dead-bang, step by step procedure. Anyone who can follow instructions can do it just as well as anyone else. The truing part -- not so much.

When truing, you do part of the work by feel:

- I think this deviation is about 8 spokes long.

- I think the move to the left is the worst deviation right now.

- I think this deviation can be cured by a 1/6 turn tightening on one side and loosening on the other.

- I think this spoke has about 1/4 turn wind in it, so I'll go 1/4 turn too far and then back it out.

- I think now's the time to switch from radial to side to side.

- I think now's the time to switch back from side to side to radial.

- I think the wheel's good enough right now, let's stress it and make sure it stays that way.

I can't make truing into a cookbook procedure. The best I can do is give some guidelines so even if your truing "gut feel" isn't fully developed, you'll be guided away from big mistakes, you'll eventually end up with a pretty true wheel, and you'll have a framework to learn your truing "gut feel."

Be Skeptical

With the exception of 1978-1981, I've ridden more than a thousand miles a year every year since 1968. And in every one of those years, I've heard a lot of nonsense from supposed authorities. There are the gram counters. The gruppo snobs. The "roads are smooth and it doesn't rain" halucenators. The Campagnolo fanboys who were certain the Gran Turismo derailleur was excellent, because after all, it was made by Campy. The "if it's not carbon fiber, it's not a frame" types. And worst of all, the guys believing transportational cycling is somehow less wear and tear than racing, and believe we should all go to the grocery store on modified roadbikes.

A lot of this nonsense is self-serving. Much of it originates from bike shops with limited inventories. Or bike shops who don't want their well-heeled customers intimidated by grease-covered DYIers buying a new rim to replace the one smashed jumping off a 2 foot curb into a pothole. Or riders who want to feel like something special with their $5000 bike, and can't bear to think someone can have as much fun and maybe go as fast on a dumpster special.

Be especially skeptical of the guy who says "you get what you pay for." Although sometimes that phrase is correct, all too often it's uttered as an opening gambit by the guy trying to reach into your wallet. The guy who insists that his skimpy little $80.00 aluminum rim is much stronger than a beefy steel middleweight rim you cannibalized from a dumpster bike. Who knows, maybe it is, but get some better info -- find someone who's ridden that rim 5000 miles, and see if that person is as heavy as you and as aggressive as you.

When someone tries to sell you a wheel with less than 32 spokes, be afraid. They'll tell you it's strong enough, be very afraid. The fact is, a lot of high end cyclo-cross bikes and tandems have 48 spoke wheels. The more spokes, the more strength. Yeah, I know, I know, the spokes they're selling you are super duper space age alloy, they're thicker, and the rim is a space age metal compatible with 18 spoke support. Keep your hand on your wallet. 18 spokes weigh less than a pound -- why in the world would you skimp on spokes?

Oh, and if some fool tells you to radial spoke your rear wheel, feign a coughing attack, turn around, and try not to let him hear you laugh.

You Can't Go Wrong Three Crossing

If you're running anything resembling 36 spokes, and if your hub sports flanges with a diameter between 1 inch and 3 inch, 3 cross will probably work. It might not be the very best, but it will give you a good, strong wheel that giddy-ups when you stamp on the pedal (always assuming your chain's in good shape and your frame isn't made of marshmellows). If you're running 36 spokes, always start assuming a 3 cross wheel, and then ask if other designs will give you substantial improvement without additional problems.

Money is Money

I probably spend more than $500.00 per year maintaining the family's four bicycles. Most of that money is spent at Orange Cycle Orlando, the biggest bike shop in. Here's why:

Unlike many bicycle shops, Orange Cycle understands that my thousand dollars every two years pays the rent and electricity every bit as well as the thousand dollars another customer spends on a new bike. Unlike many shops, they're not uncomfortable with the fact that I'm dressed in shorts and a Tshirt and maybe have some grease on my skin after removing some components. Unlike many other bike shops, they understand transportational cycling. I've personally witnessed two of their personnel biking to work, and from what I've overheard most of them bike to work. So when I speak of potholes and railroad tracks, they know what I'm talking about.

An Orange Cycle salesman named John gave me, over the phone, a 3 minute wheel lacing process, which I then used successfully to re-lace a wheel. This document is based in part on John's process.

Wherever you live, find a shop like Orange Cycle. Cycle Snob shops are a dime a dozen, but it's tougher to find a shop like Orange Cycle who know what they're talking about and understand that there's more to biking than racing or turkeying around the park on alternate Sundays. You know, a shop who can give you real advice and sell you what you need, and understand the kind of biking you do. Whether you build or buy, you need a shop that gets it, not yet another Cycle Snob.

Take it Slow

Wheel building is one of the most challenging tasks a bicycle mechanic does. Don't let your first wheelbuilding experience be like mine...

I bashed up a rim, so I took the wheel off my bike, went in a bike shop and bought a new rim and a spoke wrench. Then, sitting outside the bikeshop, without a minutes hesitation, I disassembled the wheel and began spoking on a new wheel. I didn't know whether the old wheel was 3 cross or 4 cross. I didn't even know such terms existed. An hour later I had an egg shaped thing with the hub way off to one side and a couple spokes that couldn't be stretched to fit. I took it apart and tried again, and it was a little better. I asked the bikeshop people for advice, and the third time I got it laced right but the truing was atrocious. About 4 hours after pulling up to the bike shop, I was on my way.

Don't do that to yourself. Before building or rebuilding a wheel that matters, practice on a dumpster wheel. Simulate hub bevels with marker pen if the hub doesn't have uneven bevels. Use these instructions to build a wheel. Then tear it down and rebuild, but this time simulating a rim of opposite polarity by spoking across the center line (drive flange spokes go to the non-drive side of the hub). Such a wheel would fail in usage, but you're just trying to learn the lacing process with all different rim/hub combinations. You don't even have to tighten them -- just get them to the point where they're recognized as successful lacing jobs.

Then to practice tightening and truing, build your practice wheel into a legitimate wheel, andBuild a wheel using these instructions. Then tighten and true, and practice again and again until you can get the wheel radially to 1/16 inch tolerances, and side to side to 1/4 to 1/8 inch tolerances.

This practice will take you several hours, but that way when you build your real wheel, possibly out of expensive parts, you'll be much more likely to get it right.

Please Give Me Some Feedback

I'd like feedback on this document. My email address is here:

http://www.troubleshooters.com/email_steve_litt.htm

The priority is factual errors such as wrong spoking instructions. Next is feedback on how to make the document more helpful. But any kind of feedback is more than welcome.

TireDrop.pdf

TireDrop.pdf

Before we get into the details of time trial strategies, I'll assume that you've prepared well through the winter, eaten the right things in the right amounts, have taken sufficient pre-event rest and have planned a proper

Before we get into the details of time trial strategies, I'll assume that you've prepared well through the winter, eaten the right things in the right amounts, have taken sufficient pre-event rest and have planned a proper

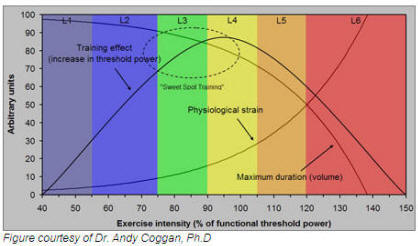

Now we're in to the big scary world of smoke and mirrors! Whether you know it or not, Functional Threshold Power (FTP) is one of the key factors of your cycling armoury. But don't worry if you don't know what it is or why it should be important to you, you're not alone.

Now we're in to the big scary world of smoke and mirrors! Whether you know it or not, Functional Threshold Power (FTP) is one of the key factors of your cycling armoury. But don't worry if you don't know what it is or why it should be important to you, you're not alone.  You could do a

You could do a

And finally the breakdown of a single interval by numbers.

And finally the breakdown of a single interval by numbers. A refreshing 21 watt increase, or 10% if you wish!

A refreshing 21 watt increase, or 10% if you wish!